In high-speed, high-stakes manufacturing environments, precision is everything. That’s why Hernon Manufacturing offers a complete line of adhesive dispensing systems designed to ensure accurate, consistent application—every time.

Unlike most adhesive manufacturers, Hernon is uniquely positioned as a single-source provider of both high-performance adhesives and the equipment that applies them. This integrated approach allows us to deliver complete solutions that reduce waste, improve cycle time, and increase product reliability across a wide range of industries.

What Are Adhesive Dispensing Systems?

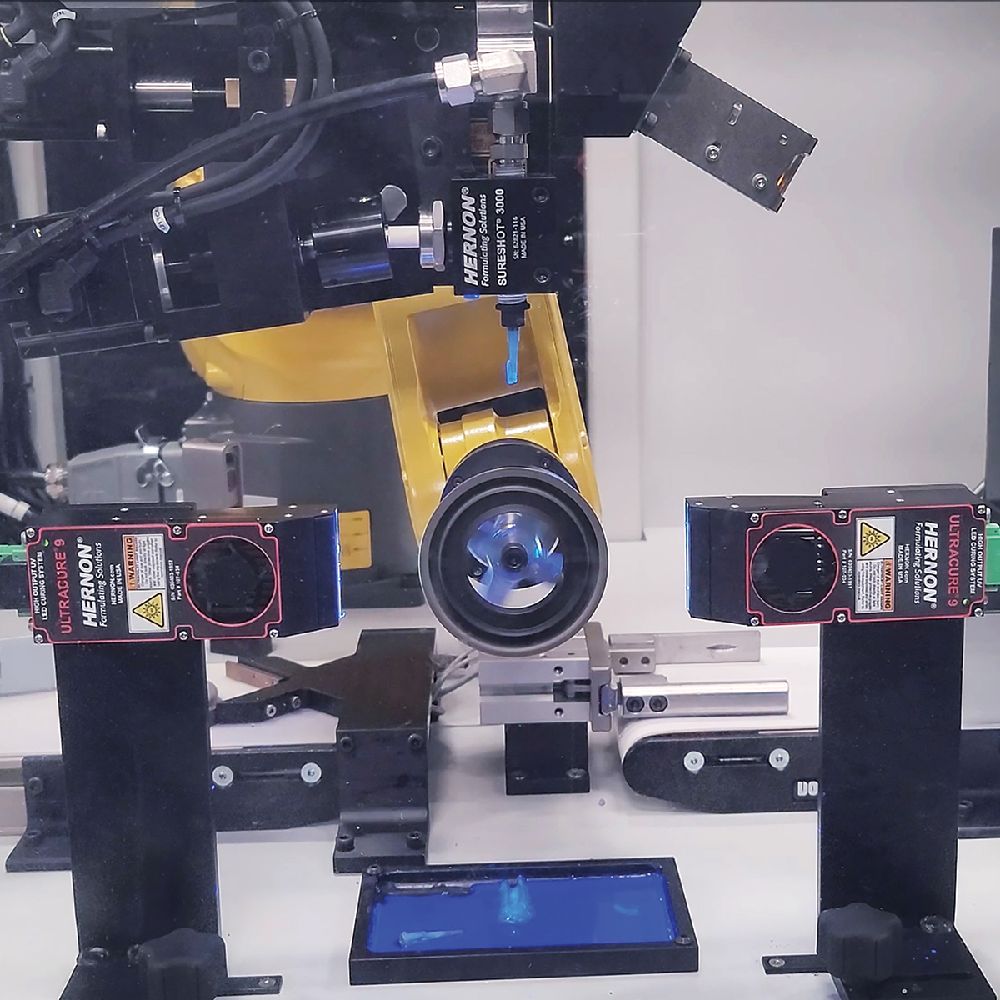

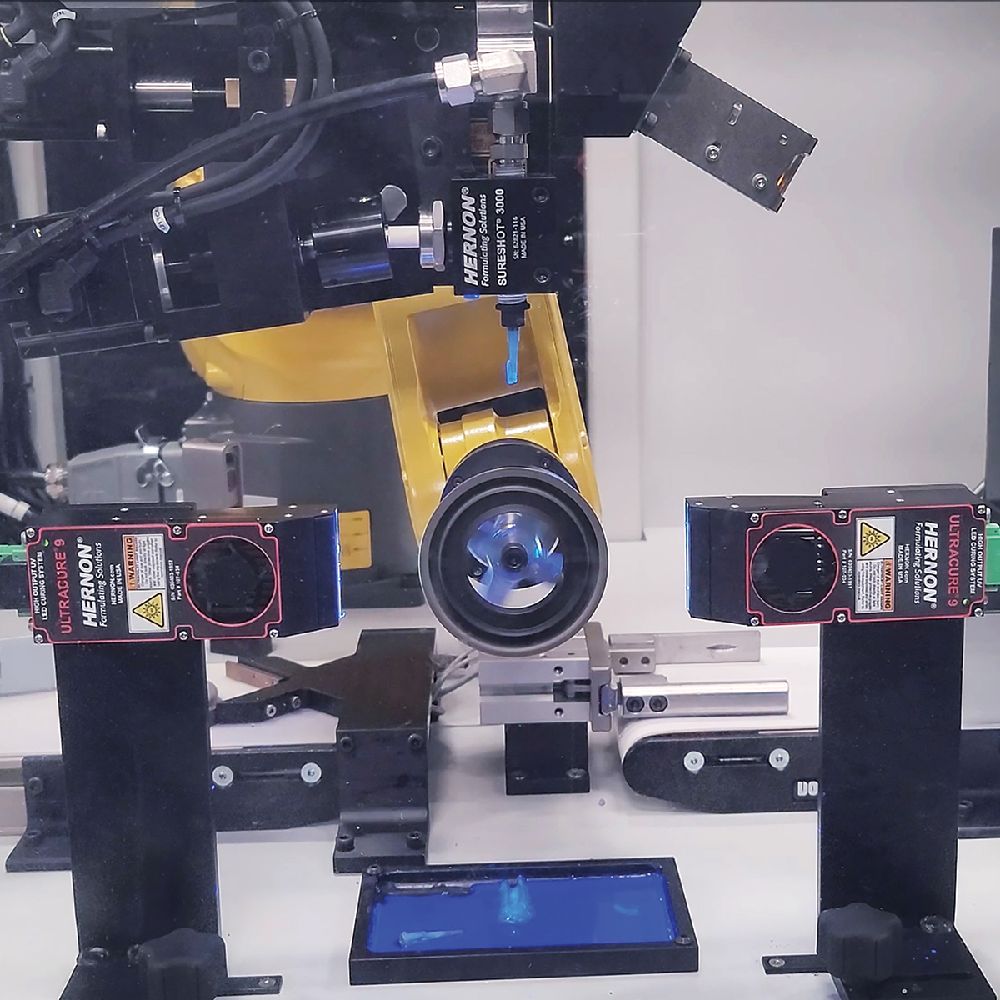

Adhesive dispensing systems are engineered machines that automate the application of bonding agents—such as anaerobics, UV curing adhesives, cyanoacrylates, epoxies, or silicones—onto parts during the manufacturing process. These systems can be customized for different adhesive types, viscosities, part geometries, and production speeds.

Whether you're bonding tiny electronic components or assembling complex automotive modules, Hernon’s dispensing equipment is built to apply adhesive with speed, precision, and control.

Why Hernon’s Adhesive Dispensing Systems Stand Out

As a vertically integrated manufacturer, Hernon doesn’t just make adhesives—we design and build the equipment that dispenses them. This creates unmatched synergy between formula and machine, giving you:

- Turnkey performance – Adhesives and dispensers designed to work together from day one

- Process consistency – High repeatability with minimal variance

- Reduced waste – Accurate shot sizes reduce over-application and clean-up

- Flexible integration – Manual, semi-automated, or fully automated systems

- Compact and scalable design – From benchtop to inline production systems

Custom Dispensing Equipment for Every Industry

Hernon’s adhesive dispensing systems are trusted by manufacturers across multiple sectors, including:

- Electronics – Precise dot or bead dispensing for PCBs, wire tacking, sensors, and enclosures

- Aerospace & Defense – High-performance application under tight tolerance requirements

- Automotive – Robust systems for gasketing, bonding, sealing, and component assembly

- Industrial Assembly – Versatile configurations for high-mix or high-volume production environments

Key Features of Hernon’s Adhesive Dispensing Systems

- Touchscreen HMI for easy control and setup

- Positive displacement or volumetric dosing options

- UV or LED curing integration available

- Servo-driven actuators for precise motion control

- Sensor feedback and QC integration for traceability

We offer standalone units, tabletop machines, and fully integrated automation cells—designed to meet your exact requirements and production goals.

End-to-End Support From a Single Partner

From product selection to implementation, Hernon supports every step of your adhesive dispensing process:

- Custom equipment engineering

- Adhesive compatibility testing

- Operator training and documentation

- On-site setup and calibration

- Ongoing service and support

With over 40 years of experience in adhesive chemistry and equipment design, Hernon is the partner you can trust to improve your assembly line’s performance and reliability.

Upgrade Your Production with Hernon’s Adhesive Dispensing Systems