When speed, strength, and accuracy are critical, UV curing adhesives offer a high-performance solution that meets the demands of modern manufacturing. At Hernon, we engineer advanced UV curing adhesive systems designed to streamline production processes, improve bond reliability, and meet the toughest industry standards.

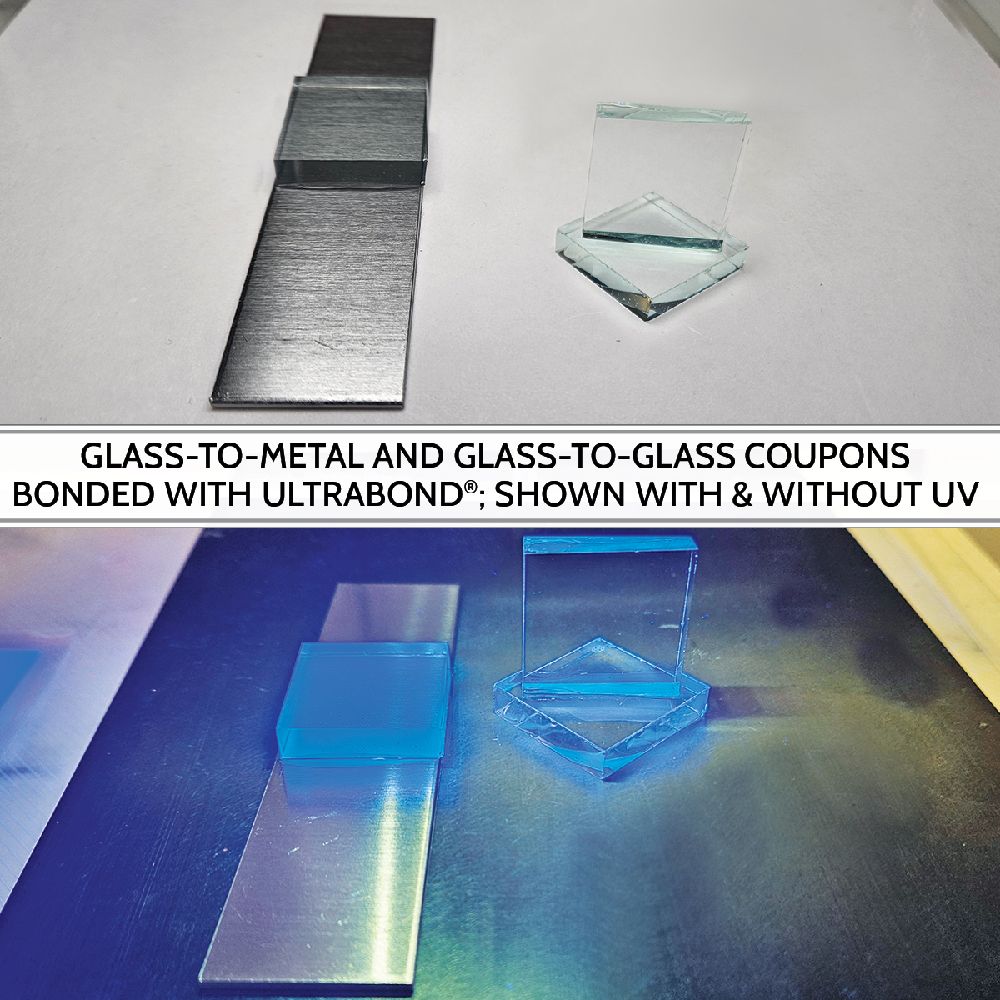

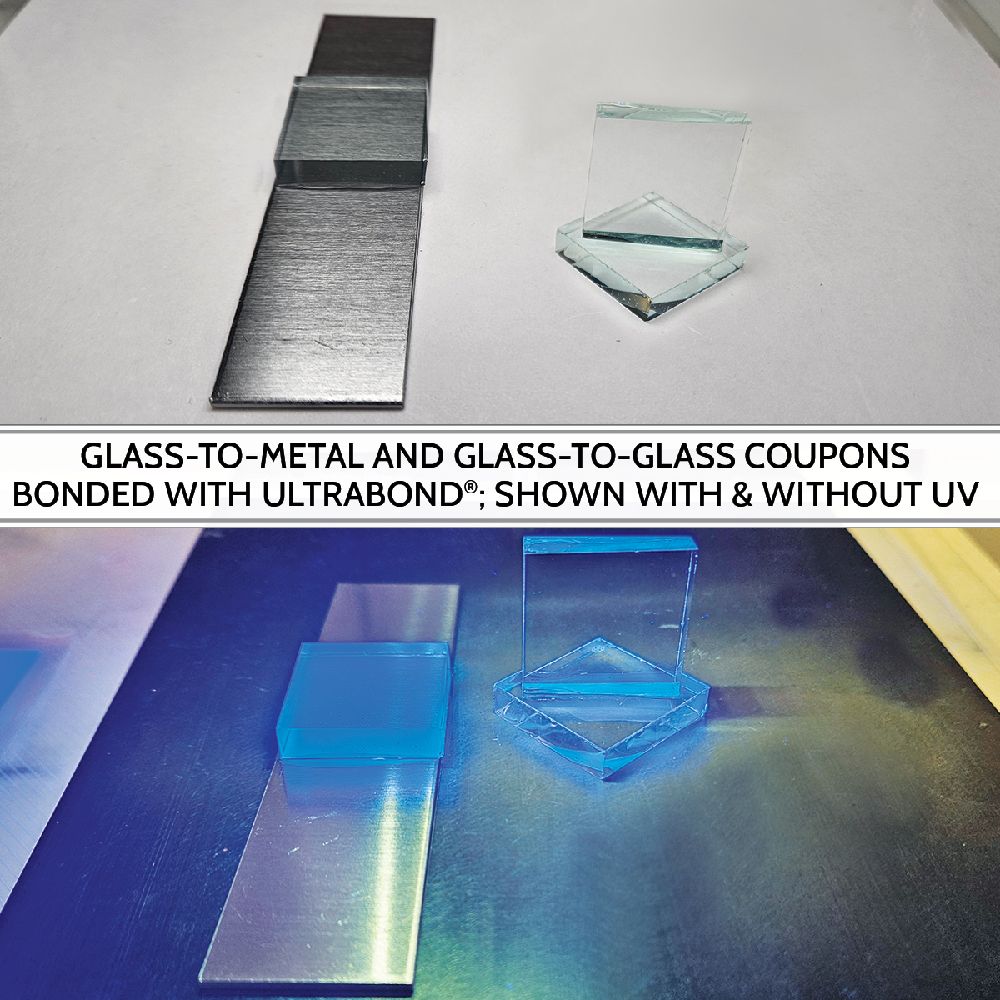

Whether you're bonding glass, plastics, metals, or dissimilar substrates, Hernon's UV cure adhesive technology delivers fast, consistent results with superior clarity and minimal waste—ideal for applications where appearance and performance are equally important.

What Is UV Curing Adhesive Technology?

UV curing adhesives are single-component materials that cure or harden when exposed to ultraviolet (UV) light. This on-demand curing mechanism offers manufacturers a reliable and efficient way to control bond timing with pinpoint accuracy.

Unlike traditional adhesives that rely on time, heat, or chemical reactions to cure, UV curing glue begins to harden instantly under a UV light source—often within seconds—allowing for faster throughput, reduced work-in-progress inventory, and cleaner assembly operations.

Benefits of Hernon’s UV Curing Glue and Adhesives

Hernon’s UV curing adhesive formulations are designed for high-precision industrial environments, offering:

- Fast curing – Bonds in seconds with minimal fixture time

- Excellent optical clarity – Ideal for transparent substrates like glass and plastic

- Tough, flexible bonds – Resistant to vibration, temperature changes, and moisture

- Controlled curing – UV light activation means no premature cure, ensuring process control

- Low to no VOCs – Safer, more environmentally friendly manufacturing

We offer a full line of UV cure adhesives engineered for specific applications including electronics, medical devices, automotive sensors, glass assembly, optics, and more.

Key Applications of UV Curing Adhesives

- Electronics: Secure delicate components without heat. Ideal for PCB assembly, wire tacking, and encapsulation.

- Medical Devices: Many excellent options for bonding catheter, tubing, and clear assemblies.

- Glass and Optics: Optical-grade clarity for bonding lenses, display covers, and lighting systems.

- Automotive Sensors: Precision bonding with rapid fixture for production line speed.

- General Manufacturing: Fast, flexible, and clean adhesive solutions for a wide range of assembly needs.

Custom UV Curing Solutions for Your Process

At Hernon, we go beyond off-the-shelf products. Our team can work with you to develop custom UV curing adhesive formulas and integrated dispensing and curing systems that match your exact requirements.

We offer:

- Tailored viscosities and cure profiles

- Blacklight, visible light, or dual-cure options

- Automated dispensing and UV curing equipment

- R&D and process engineering support

- ISO 9001 certified manufacturing

Complete Systems from One Trusted Source

What makes Hernon different? We don’t just make adhesives—we also manufacture the dispensing and UV curing equipment that brings your process to life. From benchtop systems to fully automated solutions, we provide an end-to-end answer to your bonding challenges.

If you're looking for a UV bonding solution that saves time, boosts quality, and supports high-volume output, Hernon’s UV curing adhesives are built to deliver.

Explore Hernon’s UV Curing Adhesive Systems Today.