The ammunition manufacturing industry is evolving, with a growing emphasis on efficiency, sustainability, and responsible production practices. As manufacturers face increasing regulatory pressures and environmental concerns, finding solutions that reduce waste, improve efficiency, and maintain high performance is critical.

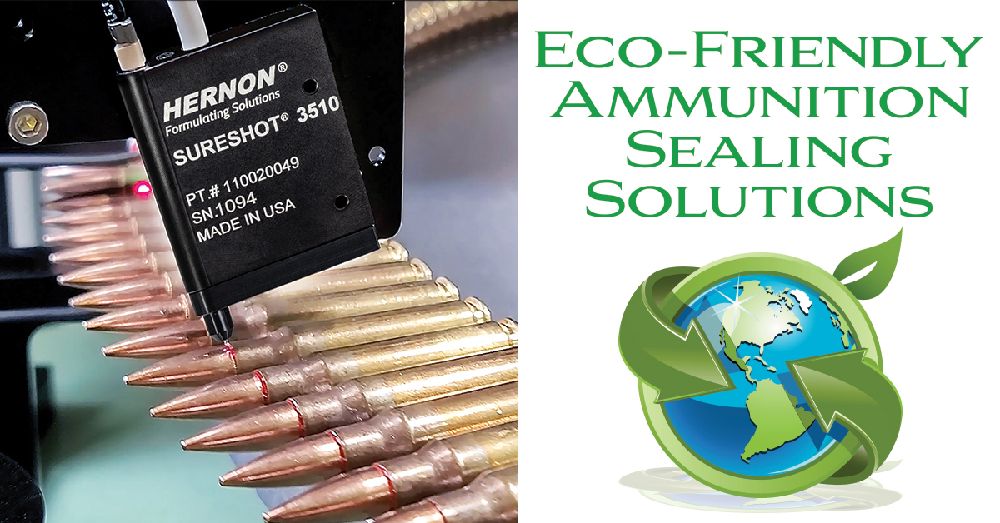

At Hernon, we are leading the way in sustainable innovation with our eco-friendly sealants and precision production solutions. These advanced technologies help manufacturers minimize environmental impact while ensuring the durability, reliability, and safety required in ammunition production.

The Shift Toward Sustainable Ammunition Manufacturing

Historically, ammunition production has relied on traditional materials and processes that generate waste, increase energy consumption, and pose environmental challenges. Today, manufacturers are seeking ways to:

✅ Reduce hazardous waste from excess materials and outdated sealants

✅ Improve production efficiency to minimize resource consumption

✅ Enhance environmental compliance with sustainable materials and processes

✅ Maintain quality and performance while adopting eco-friendly alternatives

Hernon’s advanced adhesives, sealants, and dispensing solutions are engineered to meet these needs—delivering high performance while supporting sustainability.

Eco-Friendly Sealants for Ammunition Manufacturing

Hernon’s cutting-edge sealants and coatings are designed to enhance the safety, longevity, and reliability of ammunition while reducing environmental impact.

- Green Sealants for Primer & Bullet Sealing

- Low-VOC, non-toxic formulations that reduce harmful emissions

- Precision application to minimize excess material waste

- Durable, moisture-resistant bonding to extend ammunition shelf life

- High-Efficiency Coatings for Corrosion Protection

- Eco-friendly anti-corrosion coatings that eliminate the need for hazardous chemicals

- Advanced durability to reduce the frequency of reapplications

- Customizable formulations for various ammunition types

- Precision Production Solutions for Sustainability

- Beyond materials, Hernon’s precision dispensing and application systems help manufacturers optimize production and reduce waste.

Contact Hernon today to learn more about our eco-friendly sealants and precision production solutions. Let’s build a more efficient and responsible future together!