Efficient heat dissipation is critical in today’s high-performance electronics and power systems. At Hernon, we engineer Dissipator thermally conductive adhesive solutions that deliver both strong mechanical bonds and reliable thermal transfer.

Our line of Dissipator thermal conductive adhesives is ideal for bonding heat-generating components to heat sinks, housings, or other substrates where thermal management is essential. Whether you're working in automotive, aerospace, power electronics, or LED lighting, Hernon's Dissipator adhesive technology ensures your components stay cool, secure, and operational for the long haul.

What Is a Thermally Conductive Adhesive?

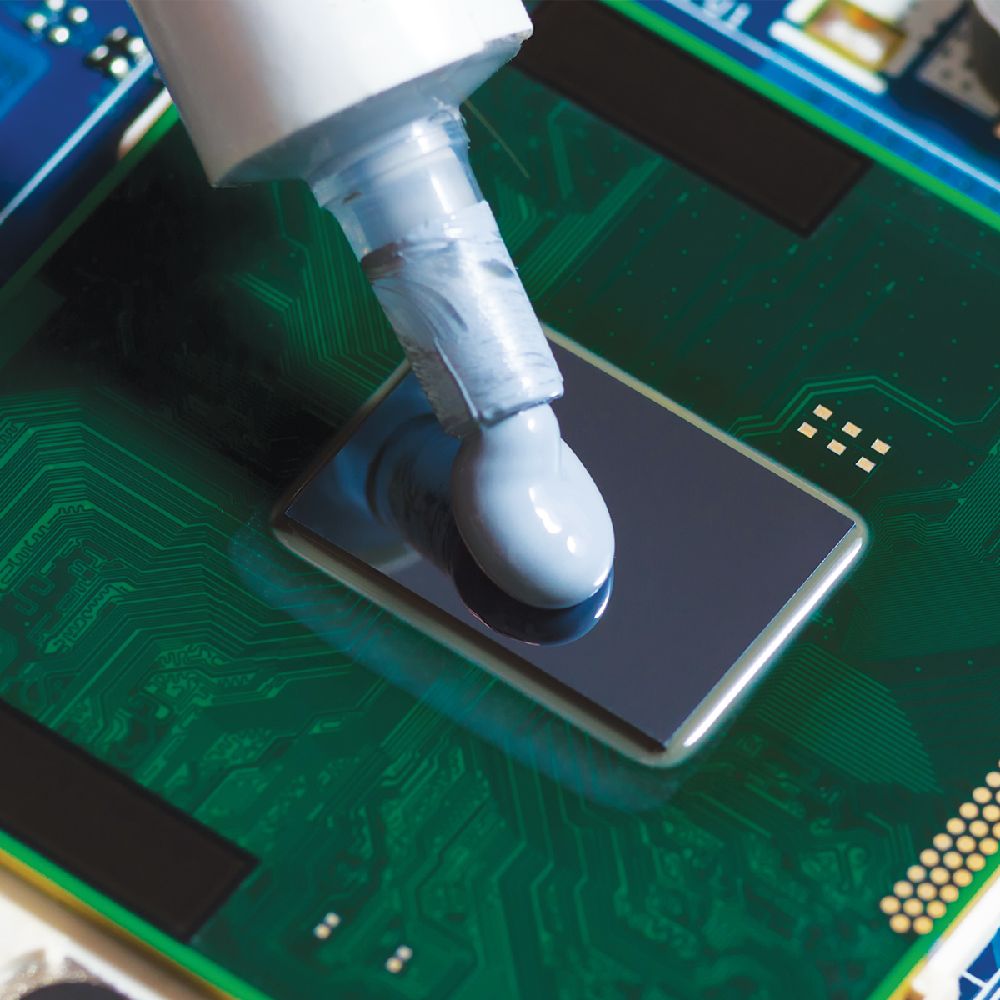

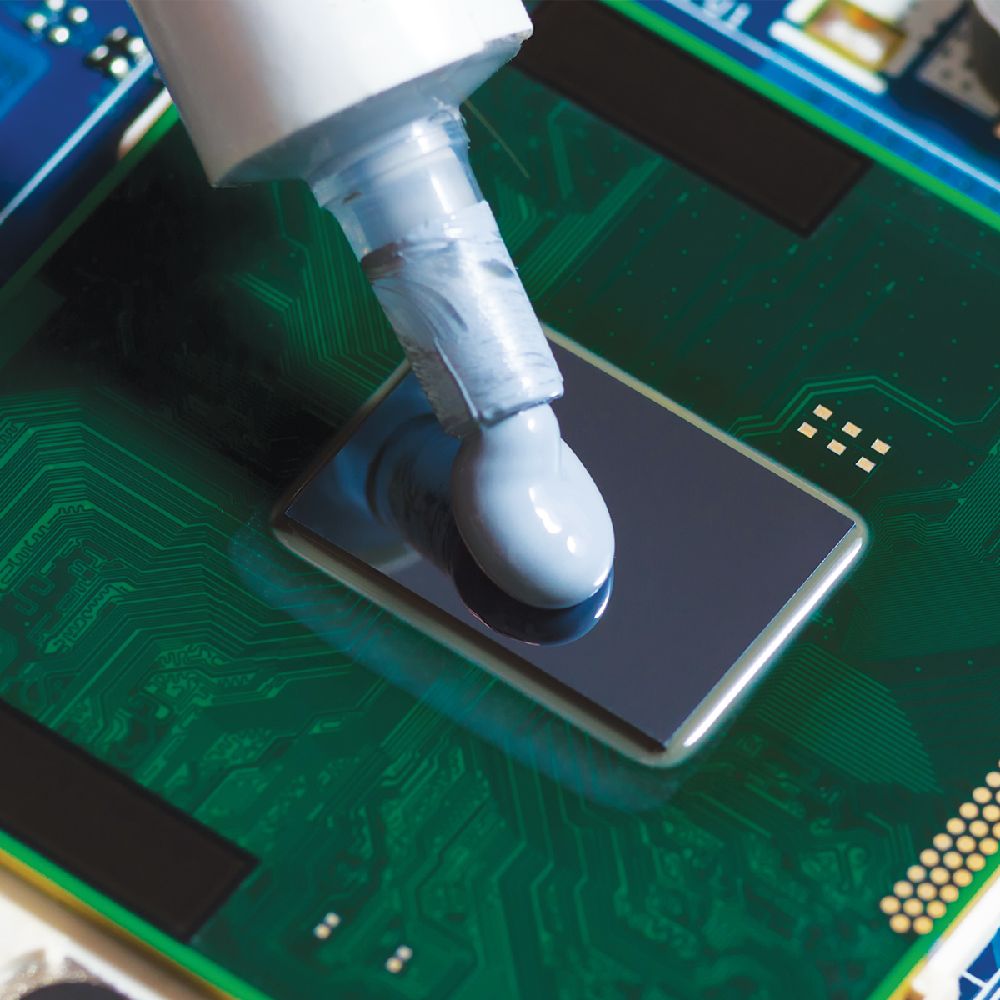

Thermally conductive adhesives are specialized bonding materials designed to transfer heat away from sensitive electronic components. These adhesives contain thermally conductive fillers like aluminum oxide or boron nitride, which enhance their ability to conduct heat while maintaining electrical insulation and mechanical strength.

Unlike traditional thermal interface materials (TIMs) that require fasteners or clips, thermal adhesives simplify assembly by bonding components directly—reducing parts, weight, and potential points of failure.

Why Choose Hernon’s Dissipator Thermal Conductive Adhesives?

Hernon offers a range of Dissipator thermally conductive adhesives tailored to meet the specific demands of your application. Our formulations balance thermal conductivity, bond strength, flexibility, and processability, making them ideal for both manual and automated production environments.

Key features of Hernon’s Dissipator thermal adhesives include:

- High thermal conductivity – Efficient heat transfer ranging from 0.5 to 3.0+ W/mK

- Strong mechanical bonding – Durable adhesion to metals, ceramics, and plastics

- Electrical insulation – Safe for use with sensitive electronic components

- Room temperature or heat cure options – Flexible for various production needs

- Low shrinkage and minimal stress – Reliable performance over thermal cycling

Applications of Dissipator Thermally Conductive Adhesives

Hernon’s Dissipator thermal adhesives are used in a wide variety of industries where heat management is crucial, including:

- LED Lighting: Secure LEDs to housings while efficiently transferring heat for longer life and stable performance.

- Power Electronics: Bond power transistors, diodes, and modules to heat sinks or enclosures to prevent overheating.

- Automotive: Thermal adhesives for EV battery packs, sensors, and control systems to maintain temperature stability.

- Telecommunications: Cool RF devices, antennas, and amplifiers without compromising performance.

- Consumer Electronics: Compact, fanless devices benefit from strong heat-dissipating bonds in limited spaces.

Customized Dissipator Thermal Adhesive Solutions

Every application is different. That’s why Hernon’s technical team works closely with manufacturers to deliver customized Dissipator thermal conductive adhesive solutions that match your production requirements.

We offer:

- Multiple viscosities for vertical and horizontal bonding

- Fast or controlled cure profiles

- Enhanced thermal and mechanical properties for extreme conditions

- Full process integration with dispensing and curing equipment

- Application testing and R&D support from our in-house lab

End-to-End Adhesive and Equipment Solutions

What sets Hernon apart is our ability to provide not just the adhesive, but also the dispensing equipment and process support needed to integrate seamlessly into your line. From R&D through production, we’re here to help you implement reliable, scalable heat management strategies.

If you're looking to improve thermal performance, simplify assembly, and extend component life, Hernon’s Dissipator thermally conductive adhesives are a smart solution for advanced design and manufacturing challenges.

Explore Hernon’s Dissipator Thermal Adhesive Products Today.