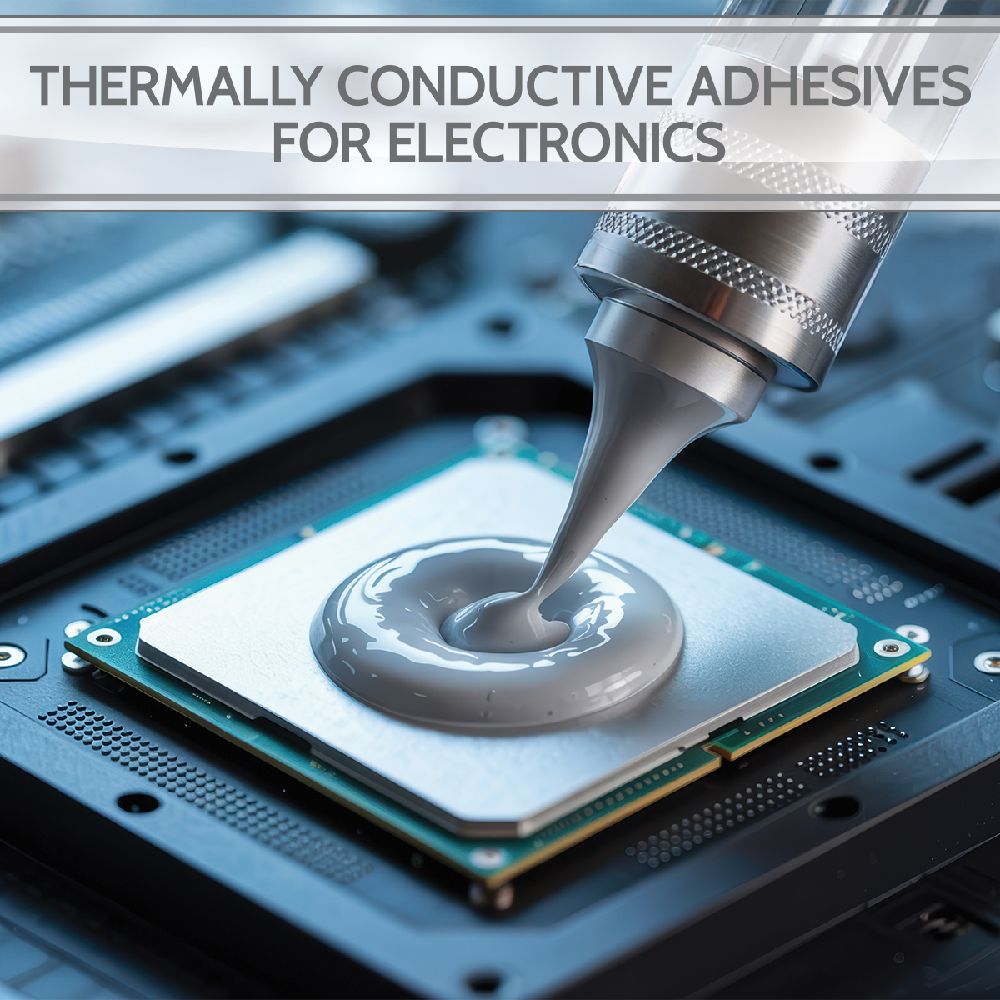

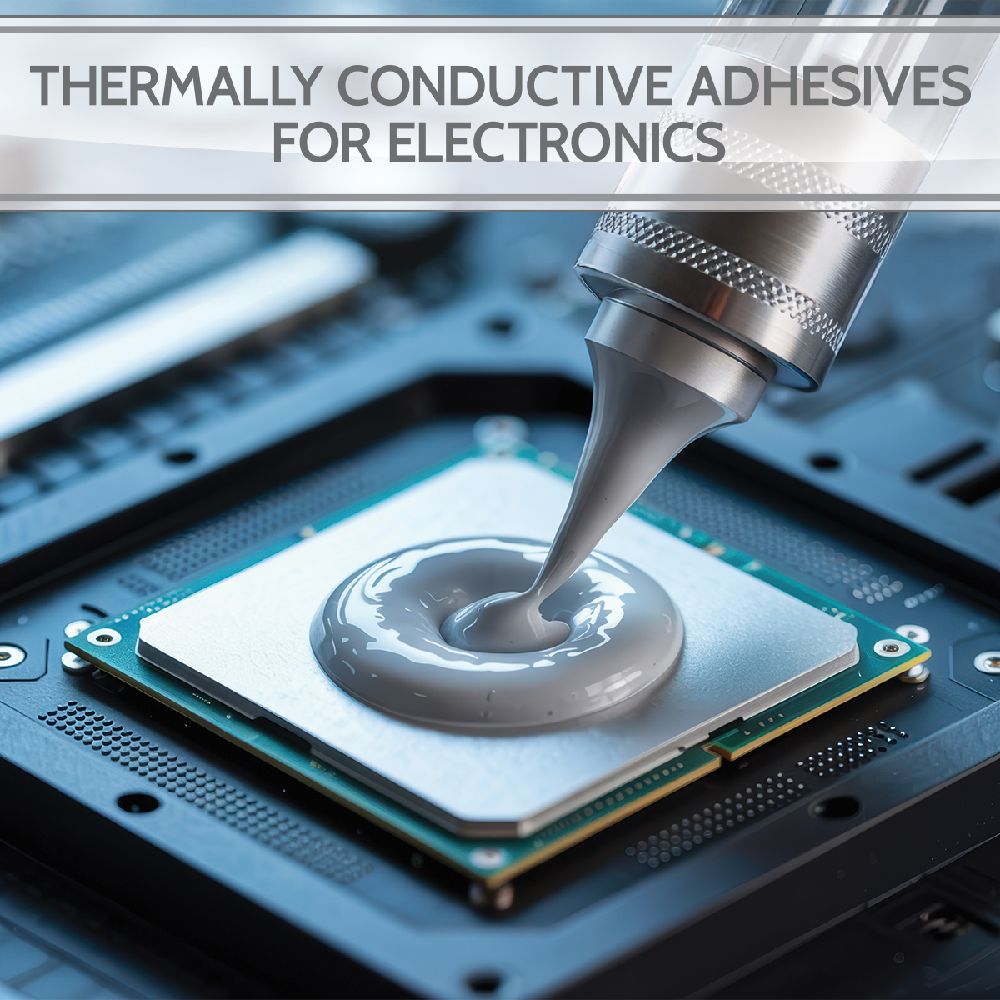

In today’s fast-paced world of advanced electronics, managing heat is more critical than ever. As devices become smaller and more powerful, thermal control isn’t just a nice-to-have—it’s essential to performance, reliability, and product longevity. That’s where thermally conductive adhesives for electronics come into play.

At Hernon Manufacturing, we understand the demands of high-performance electronics and have engineered a suite of solutions designed to efficiently dissipate heat while ensuring strong, long-lasting bonds.

Why Use Thermally Conductive Adhesives?

Electronics generate heat—sometimes a lot of it. Without proper thermal management, components can overheat, degrade, or even fail. Traditionally, thermal interface materials like pastes or pads were used to help transfer heat from sensitive components to heat sinks or enclosures. But these materials often come with limitations like poor adhesion, short lifespans, or difficult handling.

Thermally conductive adhesives provide an innovative alternative. These advanced adhesives not only bond components together but also transfer heat efficiently. The result is a simplified assembly process and enhanced thermal performance in one step.

Key Benefits of Hernon’s Thermally Conductive Adhesives:

- Superior Heat Dissipation: Our adhesives are filled with thermally conductive fillers to efficiently move heat away from critical components.

- Strong Mechanical Bonds: Unlike thermal pastes, our adhesives provide high bond strength to hold components securely in place.

- Durability: Hernon adhesives are engineered to withstand thermal cycling, vibration, and moisture—ideal for rugged environments.

- Versatile Application: Our solutions work across a range of substrates and industries, including automotive electronics, power supplies, LED lighting, telecommunications, and aerospace systems.

Featured Product: Hernon® Dissipator®

Dissipators are thermally conductive, room temperature curing adhesives that are designed for bonding electrical components to heat sinks with controlled gaps. Through a special shimming property, Dissipator® insulates the component electrically while allowing thermal conductivity. This special feature produces a constant gap of 0.005” to 0.006” between components.

Explore Hernon’s Dissipator Product Line »

Industries We Serve

Hernon’s thermally conductive adhesives are trusted by engineers and manufacturers across many sectors:

- Automotive Electronics: Control modules, sensors, and EV battery components.

- LED Lighting: Managing heat in compact, high-output lighting applications.

- Aerospace & Defense: High-reliability bonding for avionics and radar systems.

- Industrial Power Systems: Inverters, power supplies, and control boards.

View All Industries Hernon Supports »

Custom Formulations & Expert Support

Need a unique thermal solution? Hernon offers custom formulation services to meet the most specific requirements. Whether you need a faster cure time, increased conductivity, or better gap-filling performance, our team is ready to partner with you from concept to production.

Get in Touch

If you’re looking to enhance the thermal performance and reliability of your electronics, Hernon is here to help. Our adhesive solutions are trusted by engineers worldwide—and we’re ready to support your next innovation.

Let’s talk about your project:

Contact Hernon for More Info »