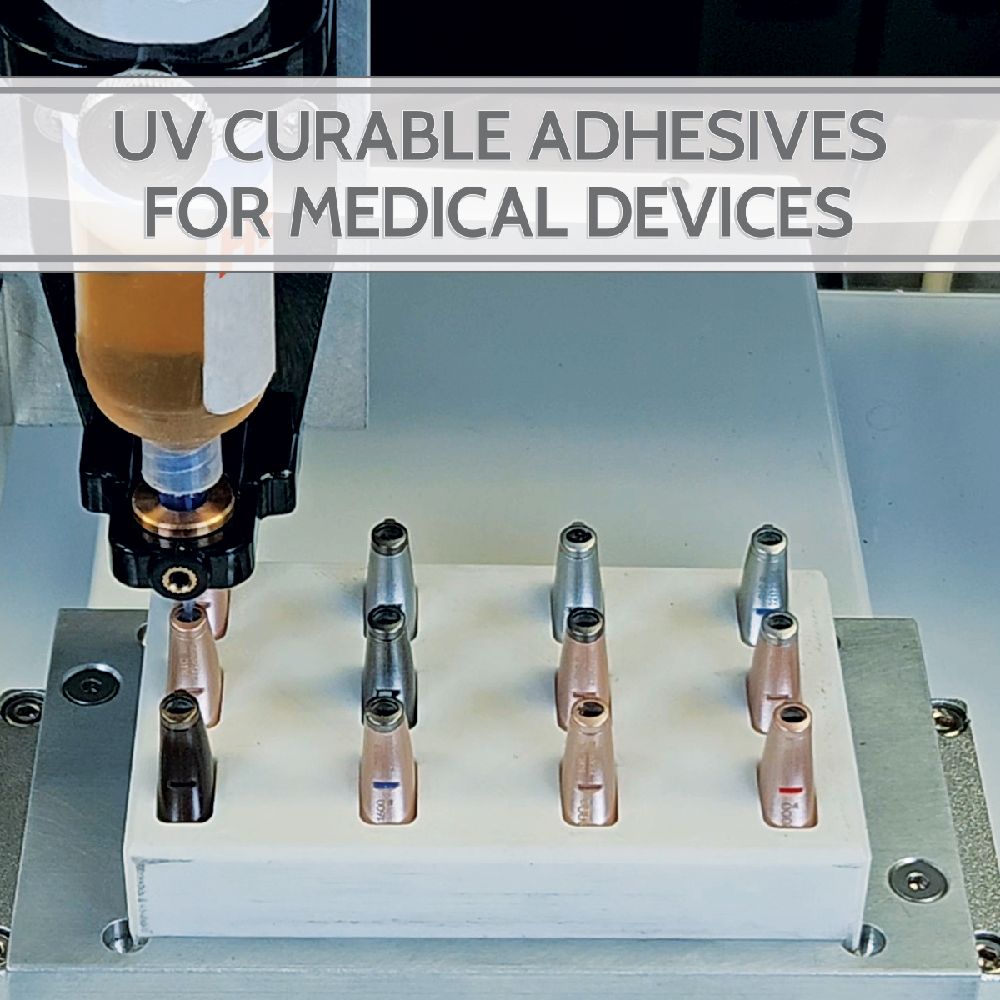

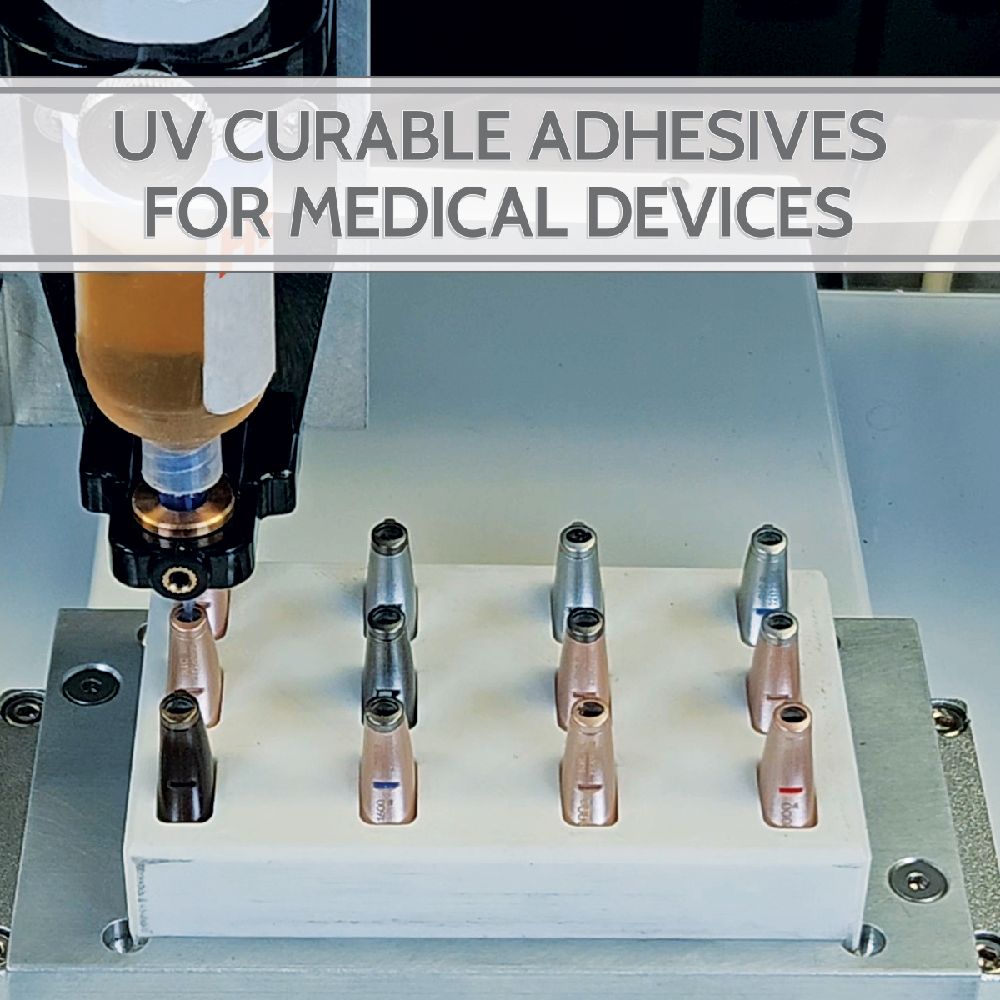

In the world of medical device manufacturing, precision, reliability, and safety are non-negotiable. Whether assembling catheters, syringes, diagnostic tools, or wearable sensors, manufacturers need adhesives that deliver strong, consistent bonds without compromising patient safety. Hernon Manufacturing offers advanced UV curable adhesives for medical devices designed to meet these exacting standards.

As medical technologies evolve, so do the materials and bonding methods used in their production. UV curable adhesives have become the go-to choice for many device manufacturers due to their fast cure times, minimal heat generation, and compatibility with delicate substrates. At Hernon, we’ve tailored our UV adhesive solutions specifically for the medical industry, ensuring regulatory compliance, performance, and process efficiency.

Why Use UV-Curable Adhesives in Medical Devices?

UV curable adhesives offer a unique combination of speed, precision, and strength, making them ideal for high-volume production and intricate assemblies. When exposed to ultraviolet light, these adhesives cure in seconds, forming strong bonds between metals, plastics, and other common medical-grade materials.

Key Advantages:

- Fast Cure Times: UV adhesives can cure in seconds, increasing throughput and reducing manufacturing cycle times.

- Precision Bonding: Ideal for small, complex assemblies where accuracy and minimal adhesive spread are critical.

- Low Heat Processing: Reduces the risk of damage to sensitive electronic or polymer components.

- Clear Finish: Excellent aesthetics and low blooming—important for optical clarity in devices like diagnostic tools or wearables.

Featured Solution: Hernon® Ultrabond®

Hernon’s Ultrabond® adhesives and coatings are one component UV curable formulas that will cure upon exposure to UV light at specific wavelengths. Ultrabond adhesives come in three different caterogies: UV curable only, UV and heat curable and UV with primer curable.

✔ Bonds glass-to-glass, glass-to-metal, some plastics, rigid & flexible PVC

✔ Can also be used in potting and coating applications

✔ Waterproofing electronic assemblies

Explore Hernon’s UV Adhesive Product Line »

Common Medical Device Applications

Hernon’s UV curable adhesives are trusted in a variety of medical device assembly applications:

- Catheter and tube bonding

- Needle assembly

- Diagnostic test cartridges

- Wearable biosensors

- Fluid delivery systems

- Endoscopic components

Our adhesives offer excellent adhesion to substrates like polycarbonate, ABS, acrylic, PVC, stainless steel, and glass—making them versatile across device types.

Regulatory Compliance & Quality Assurance

At Hernon, we know that quality and safety are paramount in medical manufacturing. Our adhesives are manufactured under stringent ISO 9001 standards.

We also provide full technical support—including product data sheets, curing guides, and assistance with dispensing systems—to help streamline your production line.

See All Industries Hernon Supports »

Ready to Improve Your Medical Device Manufacturing?

Whether you’re looking to speed up production, improve bonding strength, or enhance product reliability, Hernon’s UV curable adhesives are a smart solution. With decades of experience in critical bonding applications, our team is ready to support your success.

Connect with our technical team today:

Contact Hernon for More Info »

Kindly share products list as per to mentioned application list. Also please share medical approval certification of products...